MG Werner (left) touring Peckham Vocational Industries, Lansing, MI

MG Werner (left) touring Peckham Vocational Industries, Lansing, MI

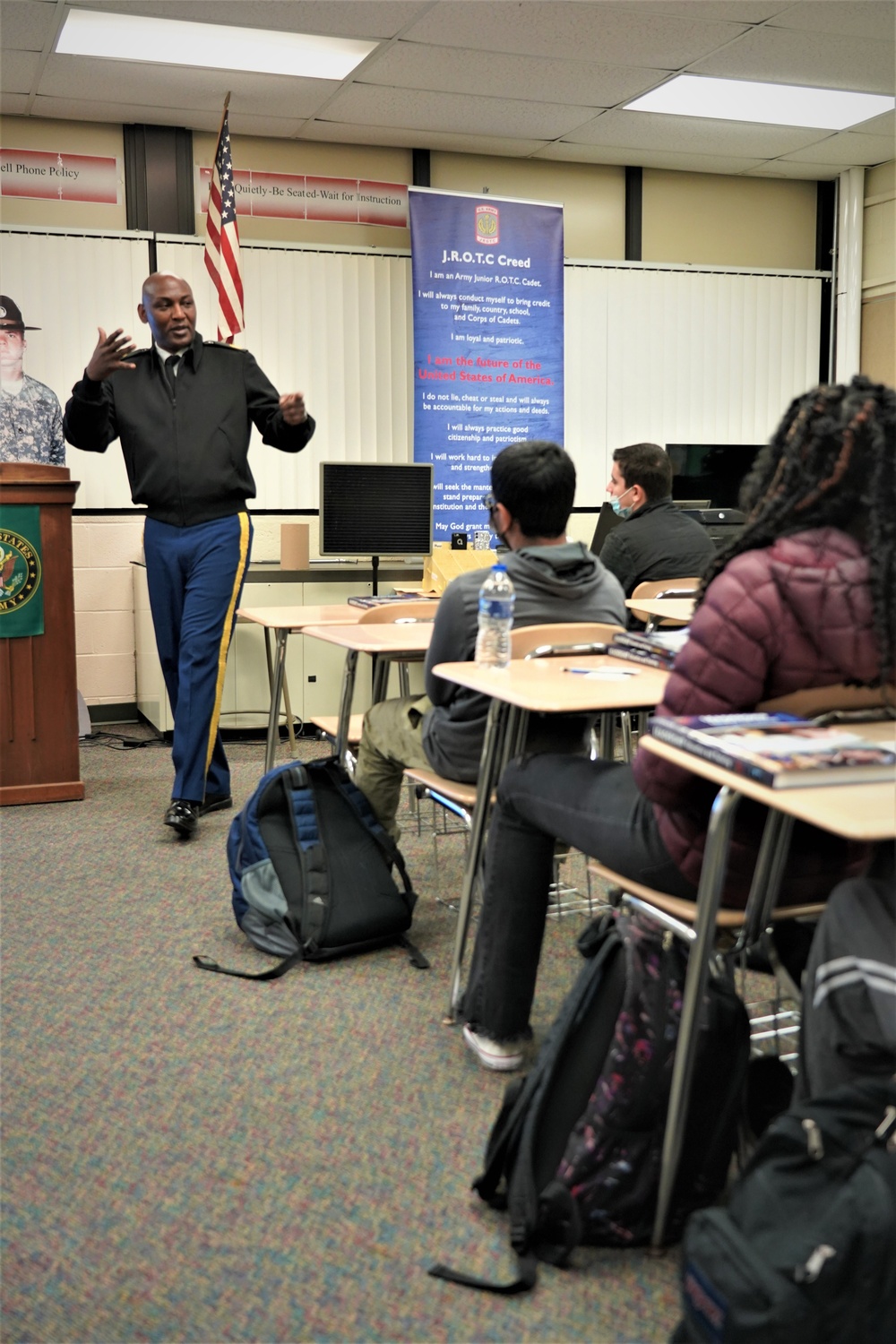

CSM Charles (right) speaking to students at Center Line High School, MI

Left photo by Scott Wakefield / Right photo by Randy Tisor

MG Werner assumed his current duties on June 12, 2020. To read his official biography, click HERE. CSM Charles assumed his current position in November 2019 [he retired July 2022]. His official biography can be viewed HERE.

MSG Half-Mast: TACOM proudly claims that “If a Soldier drives it, shoots it, wears it or eats it, we sustain it.” Tell us more about this message.

MG Werner: “If a Soldier drives it, shoots it, wears it or eats it, we sustain it” is a great motto. It’s often associated with TACOM, but it’s actually Army Materiel Command’s (AMC’s) motto because TACOM doesn’t provide meals or food to Soldiers.

We do, however, manage more than 65% of a brigade combat team’s (BCT’s) equipment. Additionally, TACOM also manages Soldiers’ individual issue items such as uniforms, weapons and masks.

In FY21, we sustained over 4,300 systems, mostly vehicle systems, as well as specialized equipment and weapons systems. We supplied more than 47,000 secondary items such as (but not limited to) engines, transmissions and systems repair parts. We manage the Central Issue Facility’s inventories and Army standard items at Military Clothing and Sales. Finally, TACOM authenticated 74,900 pages of operation, maintenance and repair procedures in 219 technical publications.

Based on these metrics, you can see we had a very productive fiscal year for 2021 sustaining the vehicle systems and equipment that move the US Army.

The command has an exciting mission supporting Army readiness. It’s one our Soldiers and civilians execute with tremendous pride.

MSG Half-Mast: Good leadership focuses on the basics or fundamentals. What are these fundamentals when it comes to TACOM-managed vehicles and equipment?

MG Werner: Troubleshooting is critical. Soldiers should ask themselves, “What could go wrong that we can identify and resolve at every stage of operation?” This starts with a commitment to comprehensive record keeping and maintenance updates. Maintenance support devices (MSDs) must be operational and current so Soldiers can accurately troubleshoot, diagnose and repair complex vehicles and weapons systems. And Soldiers must conduct proper preventive maintenance checks before operating a vehicle or weapons system and verify the equipment is fully mission capable and safe to operate.

Soldiers are required to shoot, move and communicate in austere environments and on every type of terrain; therefore TACOM-managed vehicles and weapons systems must be consistently maintained and serviced in order to meet every kind of challenge from the tip of Alaska to the deserts of Iraq.

CSM Charles: The fundamentals of sustaining any equipment are PMCS and leader involvement.

It is vital to involve leaders at all levels—from first line supervisors up to battalion leadership. Senior leaders’ involvement helps to emphasize maintenance readiness. Simply put, all leaders must continue to inspect what they expect, and this is especially true when it comes to PMCS

Developing new leaders and better maintainers often starts with sergeants’ time training and scheduled motor stables. There, Soldiers learn how to plan for any situation through readiness checks. Nothing resonates with a Soldier like learning that the equipment they use can be relied on to function as needed, especially in crisis situations.

MSG Half-Mast: MG Werner, what positive readiness trends do you see across the force? How might TACOM be leveraging technology to enhance these trends?

MG Werner: It’s always great when things are moving in a positive direction. What I see throughout the Army is unit leaders, at all levels, are taking active steps to increase their regeneration (REGEN) timeline after completing a rotation in a Combined Training Center exercise, resulting in an overall increase in readiness rates.

To maximize unit maintenance capability during REGEN, TACOM logistics assistance representatives—or LARS—are working with units to ensure they have the most interactive electronic technical manuals on their MSDs and are providing hands-on training regarding troubleshooting, diagnosis and repair of weapons systems.

MSG Half-Mast: A follow-on question for you both – what are one or two challenges that leaders and Soldiers need to watch out for and how can it or they be corrected?

MG Werner: Factors that can cause accidents and equipment failure can also lead to equipment damage, bodily harm or worse. These can be avoided. Equipment doesn’t need to fail, not if all steps learned in operations and training events are properly understood and followed. Appropriately conducted pre-combat checks can help prevent many equipment-related accidents and incidents.

I challenge unit leaders to include safety “stand downs” in their battle rhythm to ensure maintenance and operation procedures are followed. Stand downs also offer an opportunity for Soldiers to certify or recertify their tasks and their vehicles.

CSM Charles: OPTEMPO sometimes causes maintenance and supply Soldiers to expedite processes, especially in emergency situations. Rushed processes or shortcuts can result in less-than-optimum maintenance or erroneously ordering the wrong parts or both.

Integrating sustainment operations into key training events provides opportunities for Soldiers to better understand the linkage between the upkeep of their vehicles and equipment and mission accomplishment. This understanding improves Soldier and equipment readiness. It also enables TACOM to deliver the right item and quantity to the point of need.

MSG Half-Mast: CSM Charles –

PS Magazine’s focus is on caring for vehicles and equipment, but “maintenance” of Soldiers, civilians and Army families is certainly a priority. What insights do you have on the best ways the Army can enhance the readiness and resiliency of those who employ TACOM equipment daily?

CSM Charles: Improving the holistic health and fitness (H2F) of Soldiers and civilians is a key part of the Army’s cultural fitness. ACFT implementation is just a subset of H2F, as well as warrior dining facilities that offer healthy food options. Both fitness and nutrition provide Soldiers the means to achieve and sustain readiness for the rigorous tasks they do.

In addition, the Army implemented several initiatives at the brigade level that are great for our troops, such as assigning physical therapy and personal trainers at the BCT level to enhance Soldiers’ training and rehabilitation from injury.

Furthermore, NCOs who are certified as Master Resiliency Trainers contribute to our resiliency programs, as does the Chaplain Corps who supports spiritual engagements and readiness. Each of these programs is vital to the wellbeing of Soldiers. I encourage all leaders to integrate these practices into their own readiness programs.

I ask that leaders continue to leverage all available options and develop systems to integrate them into their readiness programs.

MSG Half-Mast: Share one TACOM initiative you are excited about that is new or about to happen?

MG Werner: We are modernizing the organic industrial base (OIB) at our arsenals and depots as they are the core of our mission. The process begins with a strategic vision looking ahead 15 years.

That strategic vision and its accompanying plan help us to see the best ways to address people, equipment and facilities to meet the Army’s future needs.

From a people standpoint, we look at operators, maintainers, programmers, cyber- and data-analytics experts and the ways we can “re-skill” and grow these experts. Re-skilling includes training, various recruitment strategies and partnering with local education systems.

Regarding equipment, we have partnered with the Army Combat Capabilities Development Command’s engineering community, as well as industry experts, to integrate the best practices in five areas: health and safety of the workforce, efficiency, quality, green manufacturing/sustainable industrial activity and Industry 4.0 compliance.

We will also review our facilities to lay out a lean and efficient production flow that is flexible and modular. We need to be poised and ready to quickly surge or adjust to any form of workload that the OIB is called upon to provide.

TACOM’s guidelines for ways to improve troubleshooting, organizing materials and updating manuals and equipment, combined with efforts to improve the fitness and wellbeing of Soldiers, will dovetail with the AMC’s OIB modernization strategy.

We know the Army must continue to invest in modernizing for the best interest of the industrial base. We must provide the capabilities and capacities to surge into action for large scale combat operations, reduce single points of failure, decrease reliance on foreign resources and be postured to support the Army’s new modern weapons systems.

The years ahead will bring expert technology, artificial intelligence and analytics—all of which will be leveraged to enhance combat effectiveness in every conflict situation. Our entire team must become experts in maintenance analytics, robotics, computer program logic in machining, continuous process management technology, physical facilities and process layout and remote operating capabilities.

Here at TACOM, we know we can do just that and more to sustain and defend America.